In The Beginning…

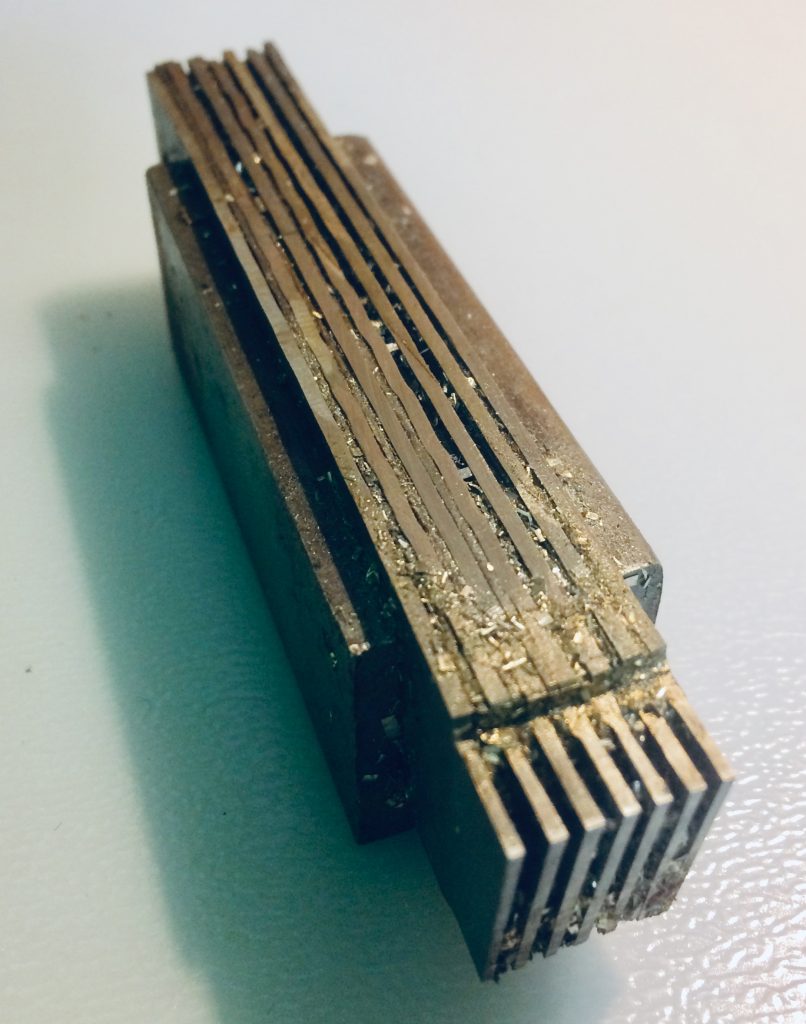

Amongst all of the stock of parts and tools that came with the purchase of J.Oliver Engines, there is a box containing the original jigs, fixtures and cutting tools that were used by the Oliver’s to make all of their engines. It has been very interesting examining them all and working out their purpose. I had the pleasure of meeting JSO a number of times at the workshop in Ferndown when Tom Ridley first took on the business around 2008. One of the first things that caught my eye was the Colchester Student lathe that still had the cylinder cooling fins tool made from a series of power hacksaw blades clamped together in the toolpost. I understood then why the fins were never spaced evenly. The cutting edges were all ground by hand and from time to time individual blades needed to be sharpened. The Oliver’s were such resourceful engineers and devised and made everything they needed themselves. The jigs they made and used were quite rudimentary but entirely functional. Being the new owner of them and realising the history behind them is indeed a privilege. It is also quite apparent the amount of hand finishing that must have gone into the final assembly of each engine.

My first brief from Tom was to measure and benchmark each variant of Ferndown engines and produce working drawings. (The Olivers never used formal drawings.) It didn’t take long to realise that no two engines were alike to the tolerances we were used to in Tom’s engineering firm!

Anyhow, I thought it might be of interest to share with anyone interested some photos of many of these original tools that produced all of those great engines. In the not too distant future I intend to follow in the masters footsteps and make a batch of Mk3’s using those very tools and methods.

Until then, Enjoy…………

Cooling fins tool.

Cylinder transfer port drill jig with interchangeable blocks for different cylinder sizes.

Crankshaft drill jigs for drilling the intake holes.

Cylinder indexing fixture for machining exhaust ports with a Woodroffe cutter.

Bearing diameter finishing tools.

Cylinder holding tool for broaching the tops of the transfer ports square.

Double diameter crank case drill and home-made backplate thread adjustable tap.

Crank case second op. lathe machining fixture.